Welcome, dear reader, to the fascinating world of manufacturing resource planning (MRP) systems and the significant impact of real-time data on its operations. In today’s fast-paced and competitive market, businesses are constantly seeking ways to streamline their processes and improve efficiency. With the integration of real-time data into MRP systems, companies can make quicker and more informed decisions, leading to improved productivity and cost savings. Let’s delve into how this integration is revolutionizing the way manufacturing companies operate and stay ahead of the curve.

Importance of Real-Time Data in MRP Systems

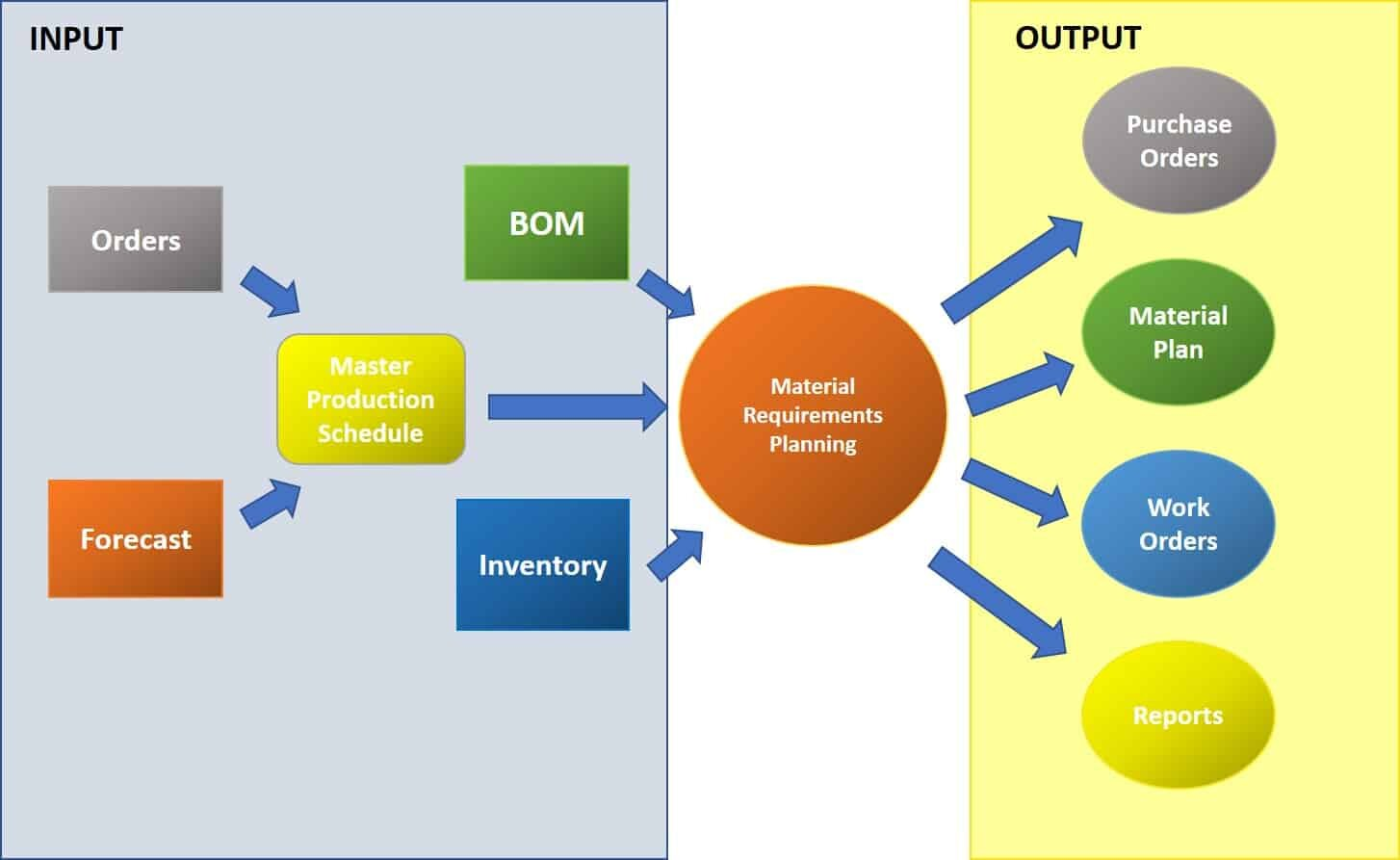

Real-time data plays a crucial role in the effectiveness and efficiency of Material Requirements Planning (MRP) systems. MRP systems are essential for manufacturers to plan production and inventory levels based on demand forecasts, lead times, and other key variables. However, the accuracy and timeliness of the data input into the MRP system can greatly impact its overall performance.

Having real-time data means that the information used by the MRP system is up-to-date and reflects the most current state of the production process, inventory levels, and customer demand. This ensures that production schedules are accurate, inventory levels are optimized, and resources are utilized efficiently. Without real-time data, MRP systems may be operating on outdated information, leading to inaccurate planning, excess inventory levels, stockouts, and production delays.

One of the key benefits of real-time data in MRP systems is improved decision-making capabilities. With access to timely and accurate data, manufacturers can make informed decisions about production scheduling, inventory management, supplier relationships, and more. This allows them to respond quickly to changes in demand, supply chain disruptions, and other unexpected events, minimizing disruptions and maximizing efficiency.

Real-time data also enhances visibility and transparency within the manufacturing organization. By having real-time insights into production processes, inventory levels, and supply chain dynamics, managers can identify bottlenecks, inefficiencies, and opportunities for improvement. This visibility enables proactive problem-solving and continuous process optimization, leading to a more agile and competitive operation.

Additionally, real-time data in MRP systems can facilitate better collaboration and communication among internal teams and external partners. By sharing up-to-date information on production schedules, inventory levels, and order statuses, different departments can work together more effectively to achieve common goals. Suppliers and customers can also benefit from real-time data integration, allowing for tighter coordination and more responsive service delivery.

In conclusion, the importance of real-time data in MRP systems cannot be overstated. By ensuring that the information used by the MRP system is accurate and up-to-date, manufacturers can improve decision-making, enhance visibility, and foster collaboration throughout the organization. With real-time data, MRP systems can operate at peak efficiency, enabling manufacturers to meet customer demand, optimize inventory levels, and stay competitive in today’s fast-paced market.

Enhancing Accuracy and Efficiency with Real-Time Data

Real-time data plays a crucial role in enhancing accuracy and efficiency in various business operations, including Material Requirements Planning (MRP). By providing up-to-the-minute information on inventory levels, sales orders, and production schedules, real-time data enables manufacturers to make better decisions and improve their overall performance. In this section, we will explore how real-time data can enhance the accuracy and efficiency of MRP processes.

One of the key benefits of using real-time data in MRP is its ability to provide a more accurate picture of inventory levels. Traditional MRP systems rely on static data that may not reflect the actual inventory on hand, leading to stockouts or overstock situations. With real-time data, manufacturers can get a real-time view of their inventory levels, enabling them to make more informed decisions about when to place orders and how much to order. This not only helps in reducing carrying costs but also ensures that the right amount of stock is available when needed, ultimately improving customer satisfaction.

Real-time data also helps in enhancing the accuracy of demand forecasting in MRP processes. By analyzing real-time sales data and customer orders, manufacturers can better predict future demand patterns and adjust their production schedules accordingly. This proactive approach to demand forecasting not only reduces the risk of stockouts but also minimizes excess inventory, leading to cost savings and improved efficiency in the production process.

Another area where real-time data can enhance accuracy and efficiency in MRP is in production scheduling. By providing real-time visibility into production processes, manufacturers can identify bottlenecks and adjust production schedules in real-time to optimize workflow and minimize downtime. This level of transparency and flexibility can help manufacturers meet customer delivery deadlines more effectively and improve overall production efficiency.

Furthermore, real-time data can also improve the accuracy of lead time calculations in MRP processes. By tracking the progress of each production order in real-time, manufacturers can accurately estimate the time it will take to complete each order and plan their production schedules accordingly. This leads to more accurate delivery promises to customers and helps in optimizing production capacity to meet customer demand efficiently.

In conclusion, real-time data plays a crucial role in enhancing accuracy and efficiency in Material Requirements Planning processes. By providing up-to-date information on inventory levels, demand patterns, production schedules, and lead times, real-time data enables manufacturers to make better decisions and improve their overall performance. Incorporating real-time data into MRP processes can lead to cost savings, improved customer satisfaction, and increased operational efficiency, making it a valuable tool for modern manufacturers.

Real-Time Data Integration with MRP Software

Real-time data integration with Manufacturing Resource Planning (MRP) software is crucial for ensuring optimal efficiency and accuracy in manufacturing processes. MRP software helps businesses plan production, manage inventory, and track orders in real time. By integrating real-time data into MRP software, businesses can streamline their operations, improve decision-making, and enhance overall productivity.

One of the key benefits of real-time data integration with MRP software is the ability to access up-to-date information on inventory levels, production schedules, and customer orders. This real-time visibility allows businesses to make informed decisions quickly, such as adjusting production schedules to meet changing demand or replenishing stock levels before running out of popular items.

Additionally, real-time data integration with MRP software can help businesses identify trends and patterns in their operations. By analyzing real-time data, businesses can spot inefficiencies or bottlenecks in their production processes and take corrective action to improve efficiency and reduce costs. For example, by monitoring real-time data on machine performance, businesses can identify maintenance issues before they cause costly downtime.

Furthermore, real-time data integration with MRP software enables businesses to better manage their supply chain relationships. By sharing real-time data with suppliers and partners, businesses can improve communication and collaboration, leading to more efficient production processes and faster order fulfillment. For example, by sharing real-time inventory data with suppliers, businesses can ensure timely delivery of raw materials and components, reducing the risk of stockouts and delays.

Another advantage of real-time data integration with MRP software is the ability to track key performance indicators (KPIs) in real time. By monitoring KPIs such as production output, inventory turnover, and order fulfillment rates in real time, businesses can quickly identify areas for improvement and take proactive steps to optimize their operations. This real-time visibility into KPIs helps businesses stay agile and responsive in a fast-paced manufacturing environment.

In conclusion, real-time data integration with MRP software offers numerous benefits for businesses looking to improve efficiency, accuracy, and productivity in their manufacturing operations. By harnessing the power of real-time data, businesses can make better decisions, optimize their production processes, and enhance their overall competitiveness in the market.

Agile Decision-Making through Real-Time Data Analysis

Real-time data analysis plays a crucial role in enabling organizations to make agile decisions. In today’s fast-paced business environment, being able to react quickly and effectively to changing circumstances is essential for success. Real-time data provides up-to-the-minute information on everything from customer behavior to market trends, allowing decision-makers to stay ahead of the curve.

One of the key benefits of real-time data analysis in agile decision-making is the ability to identify trends and patterns as they emerge. By analyzing data in real-time, organizations can quickly spot opportunities and potential risks, allowing them to make informed decisions before it’s too late. This proactive approach to decision-making is essential in a competitive marketplace where every second counts.

Real-time data analysis also allows organizations to monitor the effectiveness of their strategies and initiatives in real-time. By tracking key performance indicators (KPIs) as they happen, decision-makers can quickly identify what is working and what isn’t, enabling them to adjust their tactics on the fly. This level of agility is crucial in today’s rapidly changing business landscape, where staying one step ahead of the competition is more important than ever.

Furthermore, real-time data analysis empowers organizations to make decisions based on facts rather than gut feelings. By leveraging data-driven insights, decision-makers can reduce the risk of making costly mistakes and increase the likelihood of success. This evidence-based approach to decision-making not only leads to better outcomes but also builds trust and credibility within the organization.

Another key advantage of real-time data analysis in agile decision-making is the ability to collaborate and communicate more effectively. Real-time data allows decision-makers to share information and insights instantly, breaking down silos and fostering a culture of collaboration. This real-time collaboration enables teams to make decisions faster and more efficiently, driving innovation and growth within the organization.

In conclusion, agile decision-making through real-time data analysis is essential for organizations looking to thrive in today’s fast-paced business environment. By leveraging real-time data to identify trends, monitor performance, make evidence-based decisions, and collaborate effectively, organizations can stay ahead of the curve and drive success. With the right tools and processes in place, organizations can harness the power of real-time data to make informed decisions quickly and confidently, positioning themselves for long-term growth and sustainability.

Harnessing the Power of Real-Time Data for MRP Optimization

Real-time data plays a vital role in the effectiveness of Material Requirements Planning (MRP) systems. By having access to real-time data, businesses can make better decisions, react quickly to changes, and optimize their MRP processes for improved efficiency and cost savings. Here are five ways in which real-time data can be harnessed for MRP optimization:

1. Enhanced Visibility and Control: Real-time data provides businesses with instant visibility into their supply chain and production processes. This real-time visibility allows businesses to track inventory levels, monitor production schedules, and identify potential issues before they escalate. With this level of visibility, businesses can make informed decisions and have better control over their MRP processes.

2. Improved Accuracy and Forecasting: Real-time data enables businesses to have up-to-date information on demand trends, supplier performance, and production capacity. By leveraging this data, businesses can improve the accuracy of their forecasts, ensuring that they have the right amount of inventory on hand at all times. This, in turn, reduces the risk of stockouts, overstocking, and costly production delays.

3. Faster Response Times: With real-time data, businesses can quickly respond to changes in demand, supply disruptions, or production issues. By receiving instant alerts and notifications, businesses can take immediate action to adjust production schedules, reorder materials, or make other necessary changes to optimize their MRP processes. This agility allows businesses to adapt to market conditions and stay ahead of the competition.

4. Seamless Integration with ERP Systems: Real-time data can be seamlessly integrated with Enterprise Resource Planning (ERP) systems, providing a holistic view of the entire business operations. By integrating real-time data with ERP systems, businesses can streamline their processes, eliminate data silos, and improve communication across departments. This integration enables businesses to make more informed decisions and optimize their MRP processes for maximum efficiency.

5. Continuous Improvement and Iteration: Real-time data allows businesses to continuously monitor and analyze their MRP processes, identifying areas for improvement and optimization. By analyzing real-time data, businesses can identify bottlenecks, inefficiencies, and opportunities for cost savings. This continuous monitoring and iteration of MRP processes enable businesses to fine-tune their operations, implement best practices, and drive continuous improvement in their supply chain processes.

By harnessing the power of real-time data for MRP optimization, businesses can enhance visibility, improve accuracy, increase agility, streamline operations, and drive continuous improvement. Real-time data is a valuable tool that can help businesses stay competitive, adapt to market changes, and optimize their MRP processes for long-term success.

Originally posted 2024-03-25 02:51:50.